Details

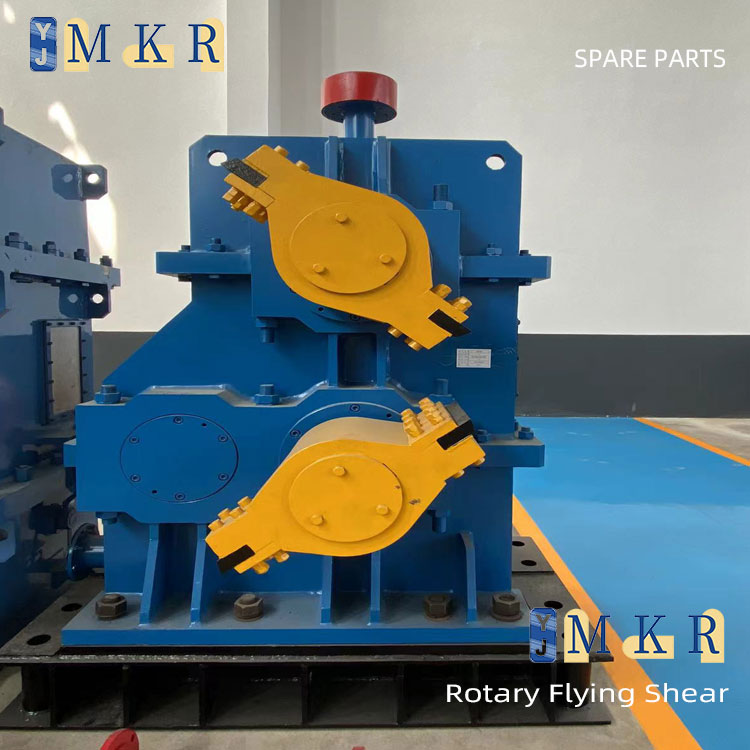

Name: Rotary Flying Shear

Weight: 7070kg

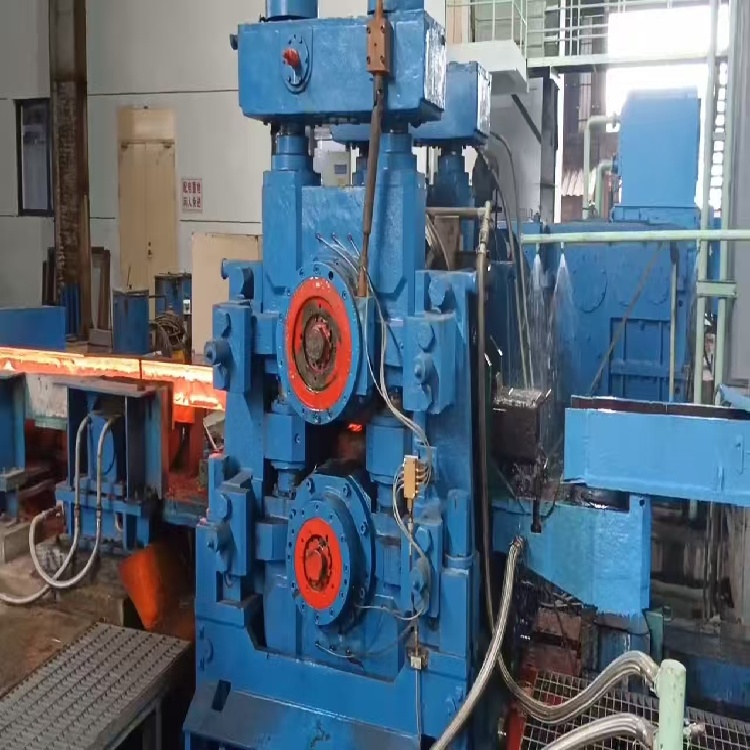

The upper and lower shear blades of the rotary flying shear are respectively installed on the upper and lower rotating shafts, and the rotating shaft is driven by the transmission system to drive the shear blades to make circular motion. When the rolled piece enters the shearing area of the flying shear, the rotating shear blades meet the rolled piece and shears it, which can achieve functions such as cutting the head, cutting the tail and sampling.

Structural features:

Shaft system and transmission: The rotary flying shear body adopts a four-axis double support hard tooth surface cylindrical transmission structure. The input shaft gear and the lower shear shaft gear are first-stage reduction transmission, and the upper shear shaft gear is second-stage reduction transmission. The upper and lower shear shaft gears are synchronized to ensure the stability of the shearing process.

Tool holder structure: The tool holder and spindle are connected by a tapered interference fit, which is easy to assemble and can ensure tool alignment accuracy.

Guide slot device: The inlet guide slot is located on the inlet side of the flying shear machine and is composed of swing guide tubes, guide tube supports, etc. It can guide the rolled piece and switch between head and tail cutting and crushing functions through cylinder drive. A swing arm device or a tapping device is added to the outlet guide slot, which can tap the cut waste into the chute to prevent steel stacking and steel jamming.

Technical parameter

Introduction to High-Spe

Introduction to High-Spe

Straightening Machine

High-Pressure Water Desc