The high-speed bar production line is a key facility for bar production. The following is its detailed introduction:

1. Overview of the production line

The high-speed bar production line is characterized by high production efficiency and high-precision product output. It plays an important role in many fields such as construction, machinery manufacturing, and automobile industry, providing a large number of high-quality bar raw materials for various industries. The specifications of the bar products it produces are diverse, which can meet the differentiated needs of different customers for bar sizes.

2. Production line process flow

(1) Billet preparation: Continuous casting billets are usually used as raw materials. Continuous casting billets have the advantages of dense structure and stable quality, providing a good foundation for subsequent rolling.

(2) Heating process: The billet is sent into the heating furnace by the steel pusher for heating, ensuring that the billet is uniformly heated to the appropriate rolling temperature.

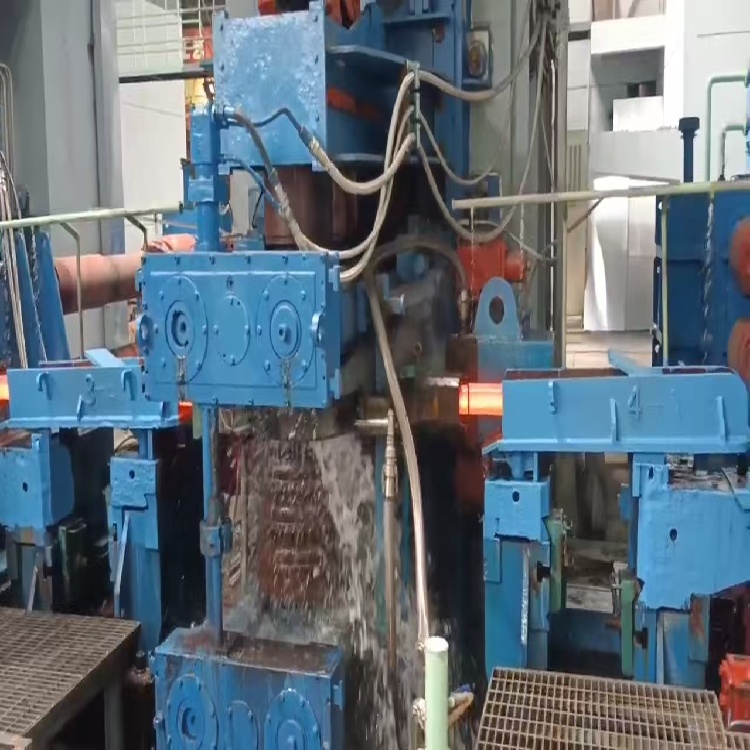

(3) Rolling: The heated billet is taken out of the heating furnace by the steel extractor and subjected to continuous rolling by the roughing mill, intermediate rolling mill and finishing mill, so that the shape and size of the rolled piece are closer to the requirements of the finished product.

(4) Cooling treatment: The rolled piece after finishing rolling needs to be cooled rapidly to control its organizational performance.

(5) Shearing and packaging: The cooled rolled piece is subjected to fixed-length shearing by cold shears, then aligned at the ends and bundled to facilitate packaging and transportation.

3. Main equipment

The main production equipment of the high-speed bar production line includes a walking beam heating furnace, short-stress mill, No.1 flying shear, water piercing device, etc. A high-pressure water descaling device is installed between the heating furnace and the roughing mill to remove the oxide scale on the surface of the billet. The 18 stands of rolling mills are arranged alternately horizontally and vertically, realizing torsion-free rolling throughout the entire line.

4. Advantages of production line

(1) High production efficiency: The production line adopts continuous rolling technology, and each process is closely connected, which can achieve high-speed and stable production.

(2) High precision products: By adopting advanced rolling technology and equipment, the dimensional accuracy and shape accuracy of the product can be effectively controlled.

(3) Production flexibility: The production line has strong production flexibility and can produce various specifications and steel grades of bar products by adjusting rolling process parameters and equipment configuration.

In conclusion, the high-speed bar production line features high production efficiency, high-precision product output, and strong production flexibility. It is a key facility for providing high-quality bar raw materials in numerous fields such as construction, mechanical manufacturing, and the automotive industry.