Details

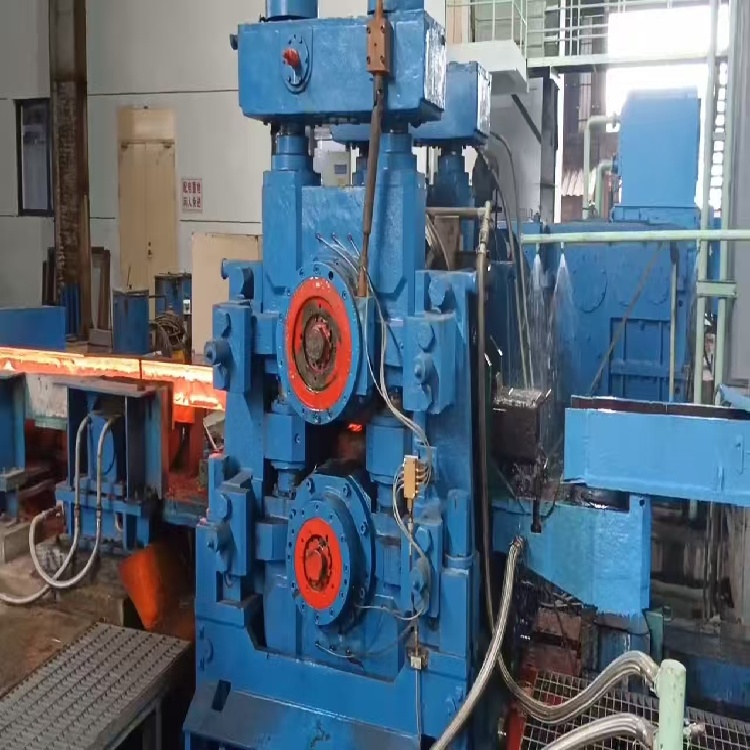

The rolling mill base supports the main body of the rolling mill through a rigid structure, ensuring stability and accuracy during the rolling process.

Principle:

Structural support

The base is usually made of castings or welded parts, and the various components of the rolling mill (such as the box, pull rods, bearings, etc.) are connected into a whole through a rigid structure. This structure can effectively transfer the rolling force, reduce elastic deformation, and enhance the rigidity and accuracy of the rolling mill.

Stress Line Optimization

In the rolling mill, the base and the screw-down mechanism together form a closed stress line loop. By optimizing the length of the stress line, the impact of elastic deformation on rolling accuracy can be reduced, while reducing equipment weight and improving operational flexibility.

Convenience of changing rollers

Some models adopt an online quick roller changing design, and the roller changing operation is achieved by replacing the stand. This design shortens downtime and improves production efficiency.

Technical parameter

Introduction to High-Spe

Introduction to High-Spe

Straightening Machine

High-Pressure Water Desc