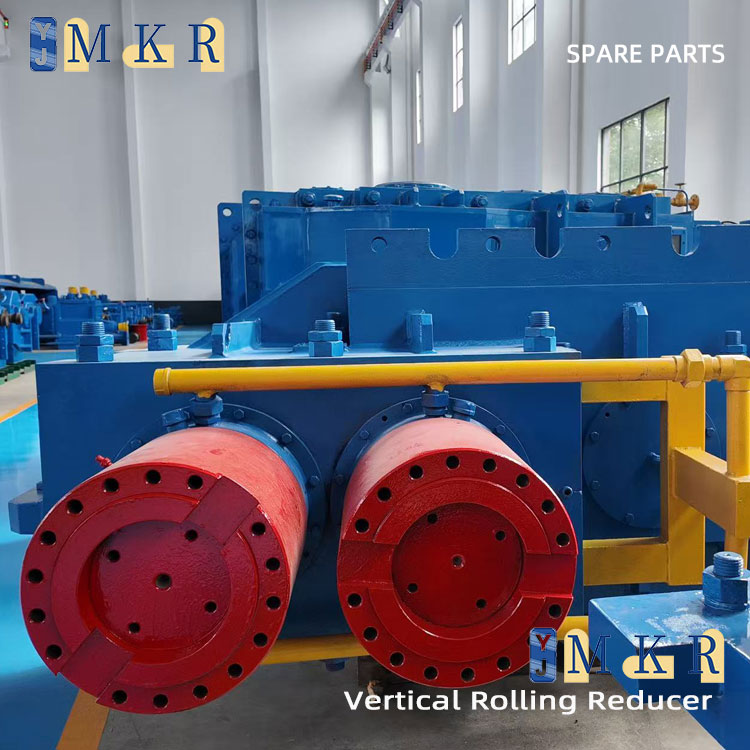

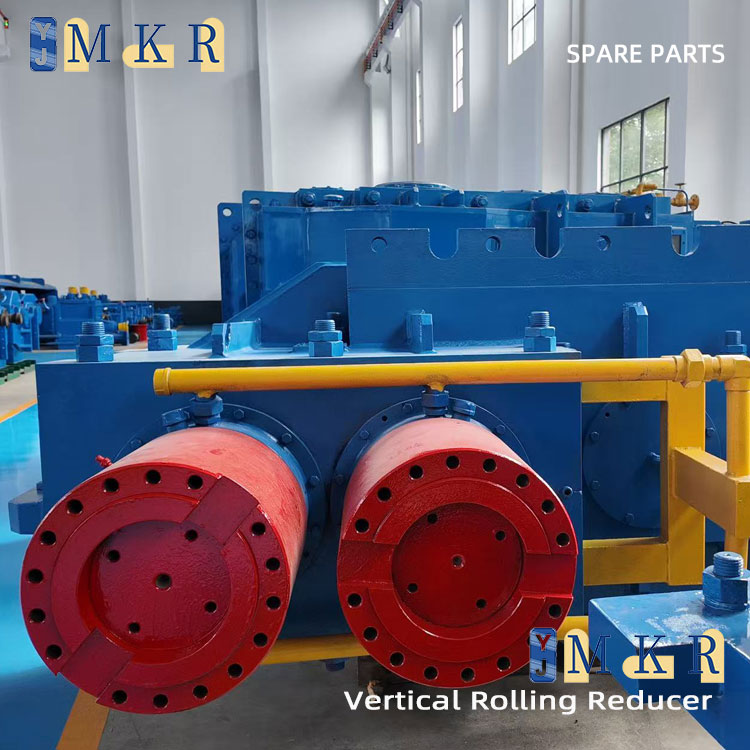

Details

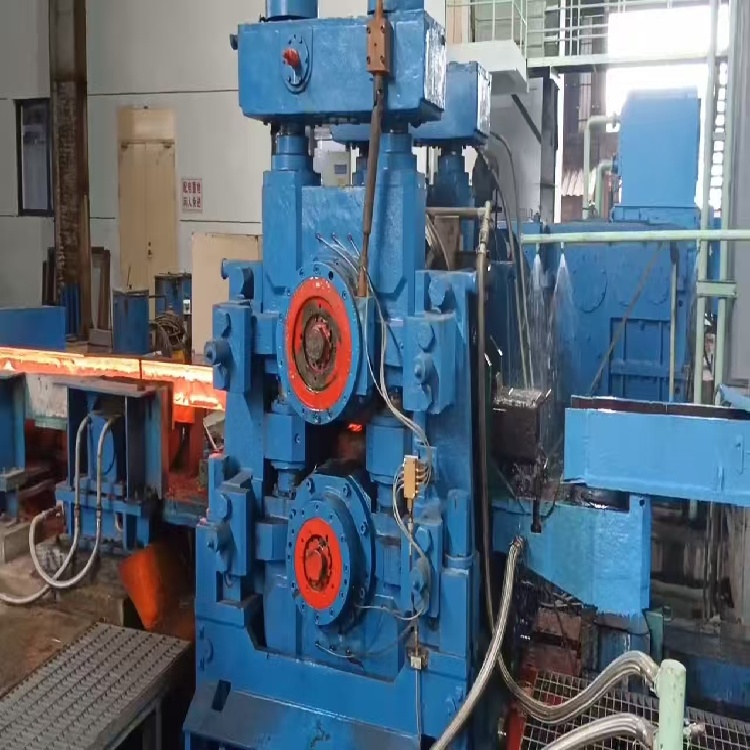

The vertical rolling reducer achieves the function of reducing speed and increasing torque through an internal gear transmission system. The power of the motor is transmitted to the primary drive gear through the input shaft. The primary drive gear meshes with the primary transmission gear, transmitting the power to the first transmission shaft. Then, the power is transmitted to the second transmission shaft through the drive bevel gear and thetransmission bevel gear. Subsequently, the power is transmitted to the lifting and rotating shaft through the secondary drive gear and the secondary transmission gear. Finally, the power is output to the rolls by the output shaft, driving the rolls to rotate.

Application features:

High torque output: Suitable for heavy load working conditions, such as the rolling mill screw-down system that needs to withstand high torque.

Stable structure: Adopts alloy steel materials and precision machining processes to ensure long-term stable operation.

Automated control: Modern reducers are often equipped with protective devices such as temperature monitoring and lubricating oil monitoring to improve safety.

Technical parameter

Introduction to High-Spe

Introduction to High-Spe

Straightening Machine

High-Pressure Water Desc