Details

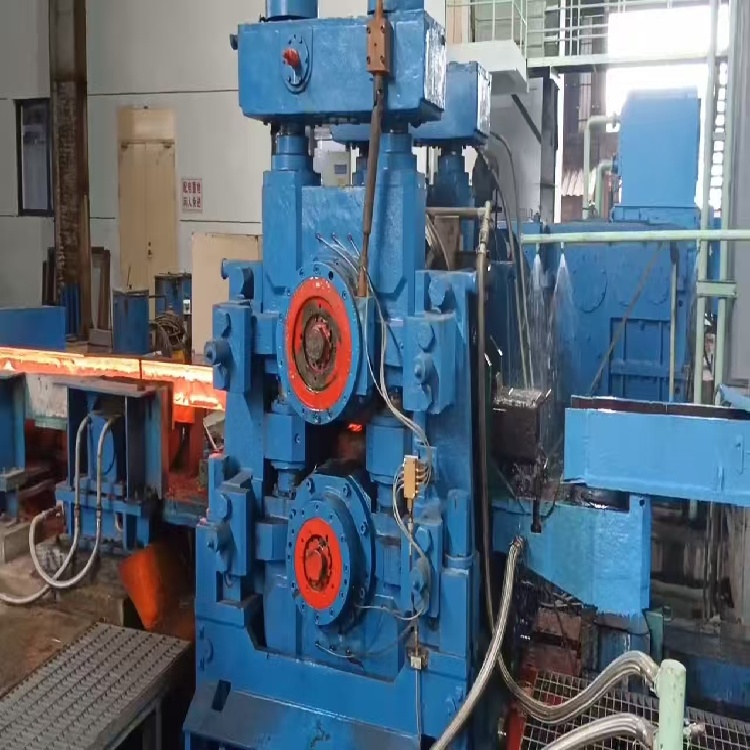

The finishing mill hydraulic station control cabinet achieves precise control of the hydraulic system by integrating electrical and hydraulic components.

Working principle:

The pressure control valve adjusts the pressure of the hydraulic system and automatically relieves the pressure when the system pressure is too high. The flow rate is regulated by using a flow control valve to control the speed and force of the actuator. The directional control valve is used to change the direction of oil flow, realize the reversing and action sequence of the executive components, and combine a variety of control methods to realize the comprehensive control and regulation of the hydraulic system.

Function:

Precise control: It can accurately adjust parameters such as pressure, flow rate, and direction of the hydraulic system, realizing complex operations like pressure adjustment, speed control and action sequence, so as to ensure the stable and reliable operation of the hydraulic system.

Safety protection: It is equipped with multiple protection functions such as overvoltage, overcurrent, excessively high oil temperature, and excessively low oil level. When the system is abnormal, it can automatically cut off the power supply or take corresponding measures to prevent equipment damage and accidents.

Our commitment

We provide not just a standard distribution cabinet, but a complete electrical control solution. From the preliminary technical consultation, scheme design, manufacturing to installation, commissioning and after-sales service, our professional team will provide full support to ensure your rolling mill equipment achieves optimal operating performance.

Welcome to inquire, we accept customized services to meet the various needs of our customers.

Technical parameter

Introduction to High-Spe

Introduction to High-Spe

Straightening Machine

High-Pressure Water Desc