Details

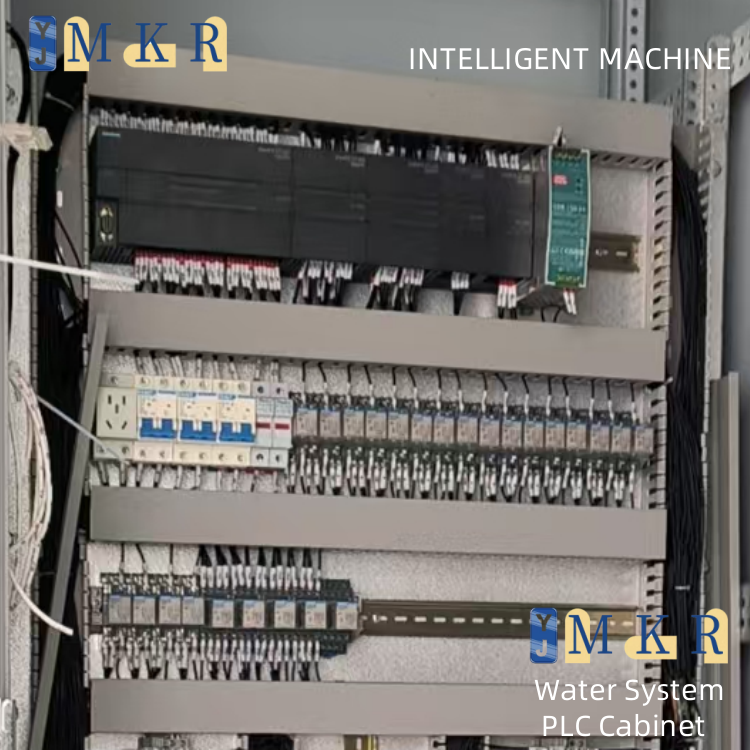

In modern water treatment and water supply and drainage systems, stable and efficient automatic control is the core to ensure the reliable operation of the system. As the “brain” of the entire water system, the water system PLC cabinet achieves efficient, energy-saving and safe water resource management through automatic control, remote monitoring and precise adjustment.

Core functions:

1. Automatic control

Automatic valve regulation: By controlling the opening and closing of electric valves and pneumatic valves, waterway switching, flow regulation or liquid level control can be achieved.

Intelligent control of pump set: Support the automatic start and stop of single/multiple pumps, frequency control (need to be matched with frequency converter) and rotation operation.

2. Remote monitoring

Key parameter monitoring: Real-time collection of parameters such as pressure, flow rate, temperature, current, and voltage in the water system, and intuitive display through HMI touch screen or remote monitoring platform. Operators can check the system operation status at any time.

Real-time fault alarm: When an abnormality occurs in the system, the PLC cabinet will immediately send out an alarm signal, display the type and location of the fault, and remind the operator to handle it in time.

Our commitment

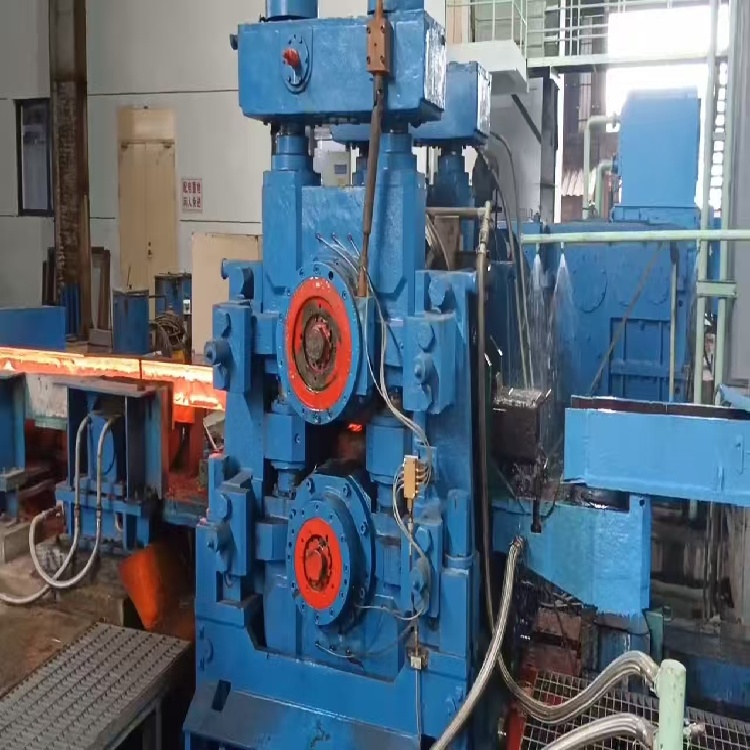

We provide not just a standard distribution cabinet, but a complete electrical control solution. From the preliminary technical consultation, scheme design, manufacturing to installation, commissioning and after-sales service, our professional team will provide full support to ensure your rolling mill equipment achieves optimal operating performance.

Welcome to inquire, we accept customized services to meet the various needs of our customers.

Technical parameter

Introduction to High-Spe

Introduction to High-Spe

Straightening Machine

High-Pressure Water Desc